TRACK

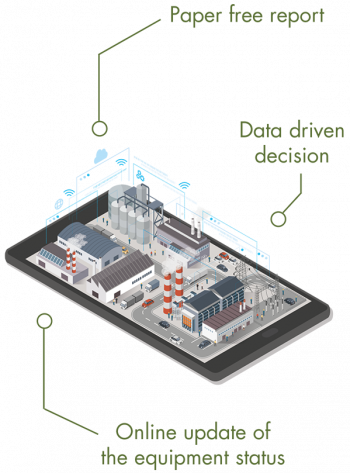

Instant and real time data

Machine uptime and efficiency

SAVE

Money due to reduction in operating costs

Time to repair

Waste

Electrical fires

INCREASE

Production capacity

Machine uptime

Manufacturing efficiency

Equipment life expectancy

OPTIMIZE

Safety

Mean time between failures

Mean time to repair

Energy consumption

Production cost

Unplanned maintenance

Manufacturing performance

Architecture

Wireless Smart Sensors

Uses

World Class Connected Maintenance Solution

Benefits

Avoid data notice errors

Reduce Mean Time to Repair

Increase life expectancy

Anticipate and prevent costly reparation

Track and notify repair times

Optimize your maintenance

Value proposition

RFID or NFC Data Notice

Listing procedure

Overview dashboard

Online reports

Improve efficiency of the maintenance operations

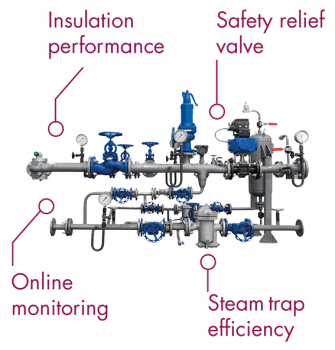

Benefits

Increase Mean Time Between Failure

Mean Time to repair

Decrease maintenance cost

Increase production capacity

Improve your profitability

Value proposition

Secure Database

Improve safety and avoid hazards

Real-time Data

Machine Learning algorithms

Machine overview

Automated email alert

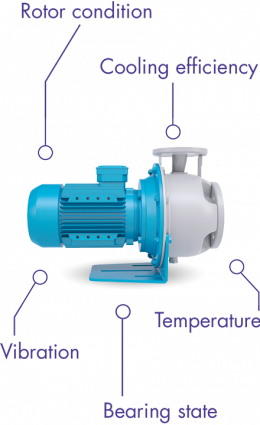

Lead and manage predictive maintenance

Benefits

Reduce probability of failure

Anticipate and prevent costly reparation

Avoid loss of energy

Help you find faults before real problems occur

Increase Energetic efficiency

Value proposition

Calorific sensors

Sensor configuration

Alarm setup

Geolocated sensors

Setup visualization

Reduce energy consumption

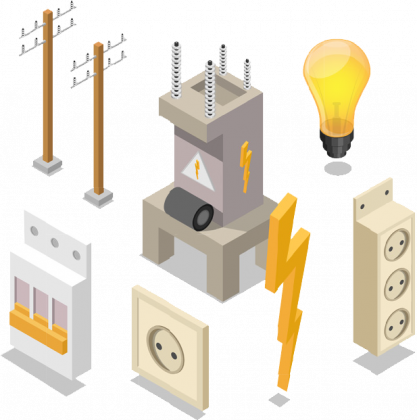

Benefits

Anticipate failure caused by wear, loose connections and humid environment

Reduce probability of failure

Anticipate and prevent costly reparation

Master your energy consumption by keeping your electric cabinet in good working condition

Avoid fires and power outage

Value proposition

Alarm management by SMS and e-mail

Description of the main components subjected to maintenance

Life cycle analysis of the product according to the environment

History of the releases

State of wear of the principal contacts

Continuous monitoring of your strategic equipment

Monitored equipment such as

Medium voltage switchgear

Low voltage switchgear

Busway

Electric Transformers

Power switchboard

Key Figures

Digital Maintenance

Our solution allows you to track your equipment

maintenance historic via RFID chip.

13%

Reduction on the Mean Time to Repair

11%

Decrease in Operating costs

Sources : Operations & Maintenance Best Practices by U.S Department of Energy Average customer feedback from 2016-2017 customer survey

SafElec

Our solution allows you to forese a failure caused by wear,

loose connection and humid environment.

35%

of industrial fires are from electrical origin

28%

Reduction on operating cost

72%

Decrease curative maintenance

Source : Operations & Maintenance Best Practices by U.S Department of Energy

OptiSteam

Our solution allows you to improve

your steam system performance.

58%

Reduction on the steam loss

6%

Decrease in

Operating cost

45k€

Savings a year

ROI less than one year

Source : Ademe (french environment and energy management agency)

Rotating Machine

Our solution allows you to forese a failure

and prevent them before they happen.

14%

Increase Mean Time between failures

9%

Decrease in

Operating cost

22%

Extend equipment lifetime

Sources : Operations & Maintenance Best Practices by U.S Department of Energy Average feedback from 2016-2017 customer survey

Contact

Contactez-nous